Fully automatic cable system with 4 stations for the processing of single conductors and a hot stamp marker for the both sided marking of single conductors.

Precision and quality for more than 20 years

Saatzer Konfektionstechnik has been a quality provider for individualized cable production based in in Ernsgaden near Ingolstadt for over 20 years. Through our decades of experience, short decision-making paths and creativity our owner-operated business provides solutions for your individual application. We develop customer specific projects and support you from every step of the way, from planning to finished product - personal, reliable and cost-efficient.

Services

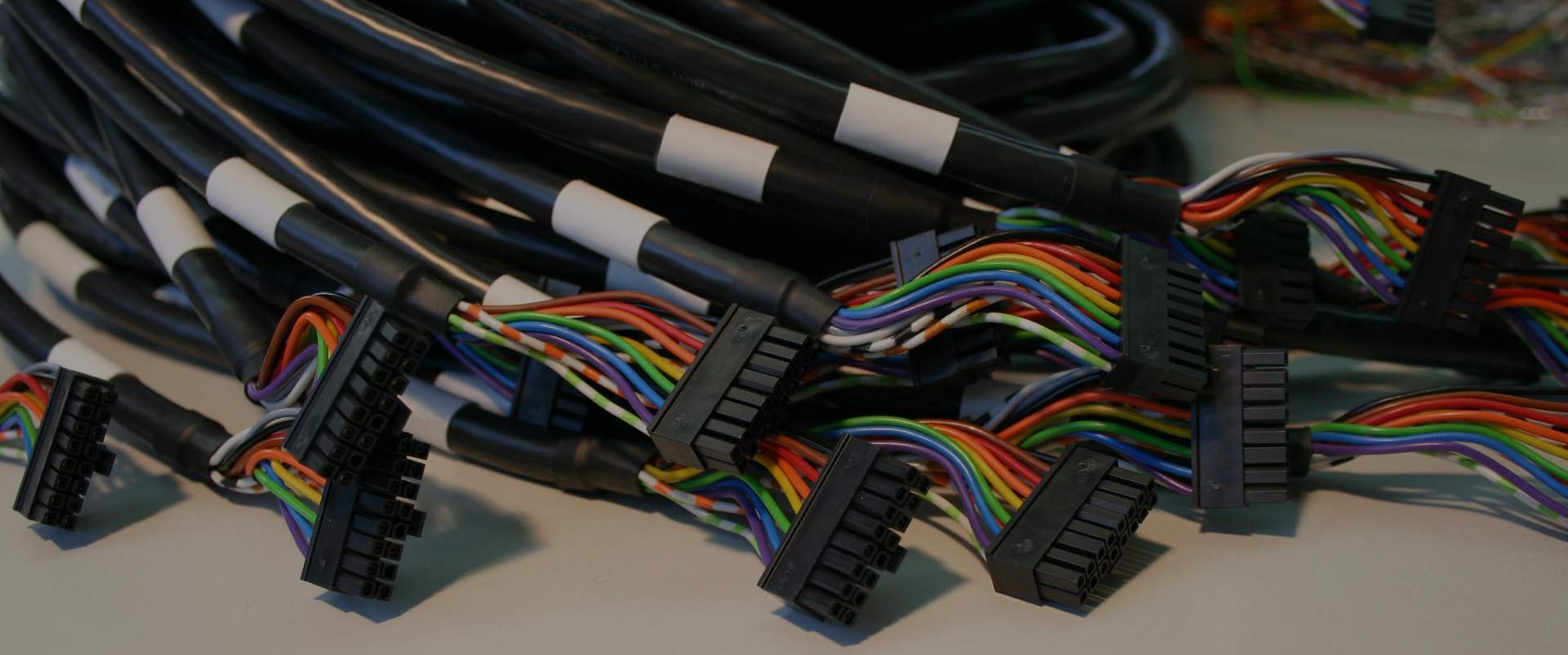

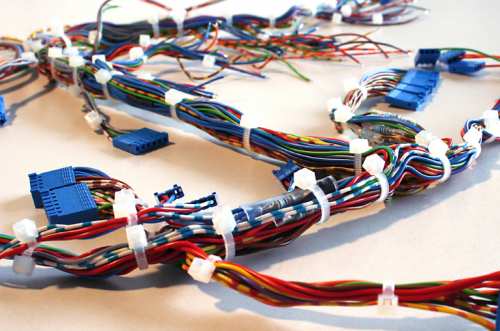

We cover a broad spectrum of services in the production of customer specific cable sets and wiring harnesses, with our manufacture process being fit for everything from prototype development [single piece] to small- or large-scale production.

Machinery

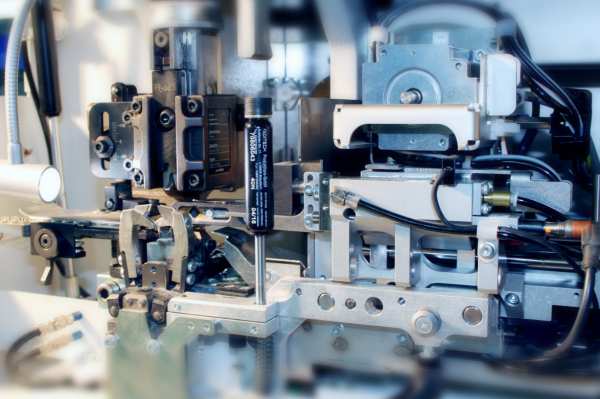

Our modern and regularly manufacturer examined machinery stands for efficiency and quality alike.

Here is an excerpt from our available machinery …

komax Gamma 333 PC + komax 26

komax Kappa 235 + Ramatech 800

Unwinder for the processing of control cables with a diameter of up to 20 mm.

komax Kappa 220 + komax 105

Unwinder for the processing of control cables with a diameter of up to 20 mm.

komax BT 712

Fully programmable stripper/crimper with integrated CFA for semi-automated processing of conductors up to AWG 10.

komax BT 711

Stripper/crimper with integrated CFA for semi-automated processing of conductors up to AWG 10.

Alphajet Tintenstrahldrucker

for precise and permanent cable marking

GLW MC 40

for the semi-automated processing of ferrules in a range from 0.25 mm2 to 4.00 mm2

Schleuniger MP 257

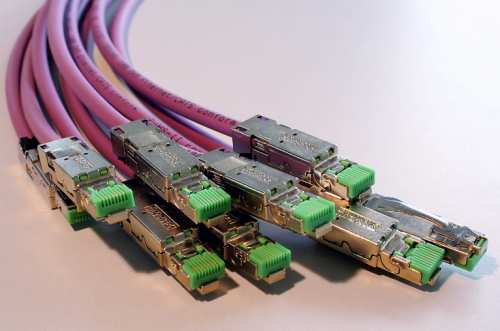

for the efficient processing of coaxial cables

Schleuniger Unistrip 2300

programmable stripper for single conductors

Quality management

Our quality management is based on the DIN ISO 9001 guidelines. In doing so we conduct 100 % electronic examinations incl. high voltage tests as per examination regulations on all of our assemblies, cable harnesses, control cables, coaxial cables, high voltage cables and so forth.Over the years we developed our own individual quality awareness and continuously optimize it. This not only includes regular training of our employees and a continuous optimization of our system processes, but also sustained investment in our machinery.

Saatzer Konfektionstechnik is UL-certified under File No. E 503967.

Wiring Harness Program -ZPFW-7+ZPFW2-8, USR/CNR Recognition of Wiring Harnesses (ZPFW2/ZPFW8)

References

Saatzer Konfektionstechnik is a long-standing partner of customers from all kinds of sectors. Our products are used for a wide variety of applications.

Sorted by sector

- automotive engineering

- aeronautical engineering

- construction industry

- medical engineering

- communication – and data technology

- industry

and much more

and much more

- underground mining and tunnel construction

- surface mining

- cranes

- hydraulic systems

- laboratory and diagnostics devices

- workshop supplies

and much more

About us

Our office building in Ernsgaden by Ingolstadt provides us with a production area of 450 m2 and modern machinery. As an owner-operated, medium-sized business has a total staff of 10 full-time employees and 10 part-time employees.

Since our foundation in 1998 we have established ourselves and continue to develop ourselves in the cable production sector in the area of southern Germany through our long-standing experience, our technical know-how and our high standard regarding the quality of our products and services.

Responsibility and sustainability

With our state-of-the-art solar system covering approx. 200 m² we are able to produce an output of ca. 27.000 kW/h per year. With this we are able to cover 100 % of our on-site power requirements and saving about 16 t CO2 per year.